charpy impact tests toughness|charpy impact test formula : traders This makes Charpy testing a popular choice for assessing the toughness of metals like steel, as well as polymers, composites, and ceramics. Here’s how the process works: The test specimen, typically 55 mm long and 10 mm square with a 2 mm deep V-notch, is positioned horizontally . Av. Henrique de Holanda, 3000 Redenção, Vitória de Santo Antão - PE. Phone. Central de Atendimento ao Cliente (81) 2121.1990

{plog:ftitle_list}

WEB了解. Fortnite. Rocket. League. Store. Robo. Recall. 游戏. 《Fortnite》 《糖豆人》 《Rocket League》 《Unreal Tournament》 《Infinity Blade》 《Shadow Complex》 《Robo Recall》.

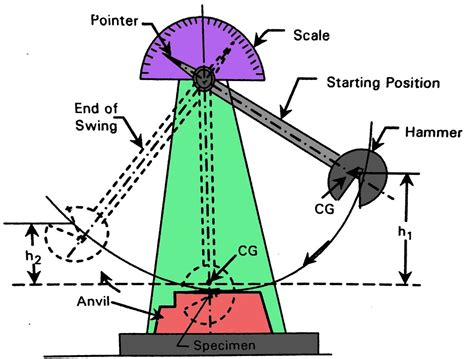

This makes Charpy testing a popular choice for assessing the toughness of metals like steel, as well as polymers, composites, and ceramics. Here’s how the process works: The test specimen, typically 55 mm long and 10 mm square with a 2 mm deep V-notch, is positioned horizontally .The Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test that determines the amount of energy absorbed by a material during fracture. This .Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its . A Charpy test determines the impact toughness of metal samples by striking them with a swinging mass. The traditional test method requires measuring the difference between the height of the striker before and after .

A widely employed method for assessing weld toughness and impact resistance is the Charpy test, also known as the Charpy V-notch test. This article provides an in-depth exploration of .The Charpy impact test provides characteristic values for the impact strength at high strain rates in the form of a surface area related value. The test measures the impact energy in relation to the fracture surface in joules.

Factors Than Can Affect a Charpy Impact Test 1. Yield Strength. In general, as a material's yield strength increases, its impact energy will decrease. In other words, materials with higher yield strength will generally . Ronald et al. [15] thought that the notch shape and strain rate would be the main discrepancies between Charpy impact and fracture toughness tests. Accordingly, they proposed a proportional relation between energy release rate G IC and consumed energy by the pre-cracked impact specimen under slow-bend condition. However, it should be noted that .

tensile testing machine for biological tissues

Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered. . The Charpy .Impact data: the room temperature Charpy impact strength of extruded and forged section given the recommended heat treatment of 2 h/1150°C/WQ + 8 h/800°C/AC is in the region of 111 J. Long-term embrittlement has been investigated by room and elevated temperature Charpy impact testing of extruded and forged section given the recommended heat . Charpy Impact Testing, also known as the “Charpy V-notch test,” is a standardized test method used to determine the impact toughness of materials, particularly metals. It assesses a material's ability to absorb energy during fracture when subjected to a sudden impact.The two most common methods to determine toughness include: Izod and Charpy Test. Key principle These impact methods are based on the common principle of: applying the load at a high rate, and; . Key advantages of impact tests Values of toughness are not directly used for design purposes. They only indicate the ability of the material to .

In order to reveal the toughness of our designed steel, standard Charpy V-notch impact samples were prepared. Ultrahigh Charpy V-notch toughness of 300–450J was achieved with strength as high as . A Charpy impact testing apparatus, a device with a pendulum with various locking points at specified heights and a fixture to hold the test specimen, is used to determine Charpy impact strength. The standard test specimen is described in ASTM E23. It has a V-shaped notch cut into it. It is oriented so that it is simply supported on both ends .As was written, toughness can be measured by the Charpy test or the Izod test. These two standardized impact tests, the Charpy and the Izod, are used to measure the impact energy (sometimes also termed notch toughness). The Charpy V-notch (CVN) technique is most commonly used. Both of these tests use a notched sample of defined cross-section. Fracture Toughness (K IC) is an important material property in fracture mechanics.There are numerous literatures that suggest the use of relationship between the fracture toughness (K IC) and impact strength (CVN).In this investigation, the relationship between K IC and CVN was used to determine the fracture toughness of high strength, low .

History of the Charpy impact test. The history of Charpy V-notch impact testing dates back to the early 1900s when French engineer Georges Charpy developed a standardized method for testing the impact toughness of materials, particularly metals. His work led to the creation of the Charpy impact test, which involved striking a standardized specimen with a .

An impact test consists of a striker hitting the test specimen to transfer a large force in a short time.You can use a drop tower or a pendulum tester to achieve such large forces.. A striker is dropped vertically from a height for a drop tower test and uses gravity to achieve the necessary impact energy. Similarly, in a pendulum test, the striker is fixed to an arm that swings like a .

Mechanical testing of welds. Philippa Moore, Geoff Booth, in The Welding Engineer s Guide to Fracture and Fatigue, 2015. 9.5 Charpy testing. The Charpy test measures the energy absorbed when a notched bar of material is struck with a fixed-weight pendulum swung from a given height. The absorbed energy (in joules) is also referred to as the impact toughness of the material.The Charpy impact toughness of aluminum alloys is reduced via introduction of the reinforcement (Singh and Lewandowski, 1995; Lewandowski and Singh, 1996). Figures 7 and 8 summarize recent data obtained on 2XXX, 6XXX, and 7XXX materials in both unnotched and notched conditions, respectively. Although the data are somewhat limited in comparison to the . ASTM E2248 – 18: Standard Test Method for Impact Testing of Miniaturized Charpy V-notch Specimens.; Ductile to brittle transition in impact testing. Carbon steel and low alloy steel are characterized by the fact that the .The Charpy V Notch (CVN) test is a basic method for defining toughness and, in this process, toughness is defined in “joules or ft lbs” at the “temperature of test”. There are other, more complex methods but the CVN test is cheap, is a good .

For these cases, the remedy involves making use of fracture toughness estimates from simpler and readily available mechanical tests, such as the Charpy V-notch (CVN) impact test [7], [8], the drop-weight test for measuring the nil-ductility transition temperature (NDTT) [9], [10], [11] and the dynamic tear (DT) test [9], [10], [12]. Because of .

The Charpy impact test is performed to evaluate the resistance of the metal to breakage by flexural shock or impact load according to standard test method ASTM D6110. . This absorbed energy is a measure of a given material’s notch toughness and acts as a tool to study temperature-dependent ductile-brittle transition. Tensile and Charpy impact tests. The mechanical properties were evaluated through uniaxial tensile testing (NCS GNT300) of ASTM-E8 standard specimens (diameter: 5 mm, gauge: 25 mm) at room .Impact Toughness. The impact toughness (AKA Impact strength) of a material can be determined with a Charpy or Izod test. These tests are named after their inventors and were developed in the early 1900’s before fracture mechanics theory was available. Impact properties are not directly used in fracture mechanics calculations, but the .

Charpy Impact Test Specimen Dimensions. A Charpy test specimen, which is placed horizontally into the machine, is typically a 55 x 10 x 10mm (2.165" x 0.394" x 0.394") bar with a notch machined into one of the faces.

Testing machines for determination of the impact strength of plastics and metals . which has also earned these machines the designation of Charpy impact testers or Charpy impact testing machines. The base components of a Charpy tester are the machine frame, a weighted pendulum rod with hammer, a dial gauge, specimen supports, and a safety . A variety of tests have been developed to measure the toughness of a material. Some test methods can be used directly in the design of a part, while other test methods cannot be. Charpy Impact Test. The Charpy V notch test is a test for measuring impact strength in which a small notched bar is loaded dynamically in three-point bending.

Extensive efforts in the development of instrumented Charpy tests began in the 1960s and 1970s with the advent of fracture mechanics and pre-cracked Charpy V-notch samples, when the role of instrumented impact testing in the evaluation of dynamic fracture toughness was examined. As a result, the complex CTOD test, which is costly, can be determined by a simple low-cost Charpy impact test, providing guidance for the widespread application of Q690 high-strength steel in low . This paper presents results of fracture toughness and Charpy impact tests of 4 steels prepared by metal injection moulding (MIM) method: AISI 4140, 4605, 17-4 PH and SS 420W Grade.

V-notch Charpy impact test has been widely used to qualify toughness of steels and welds (e.g., [5, 6]). In this work, instrumented Charpy tests of pre-charged steel specimens were conducted at ambient temperature using a pendulum machine with a capacity of 750 J. Two to three repetitive specimens were tested for each pre-charging condition.

charpy impact test sample

WEB4 de ago. de 2019 · 原文链接:. https://stackoverflow.com/questions/57350961. 我正在处理ioredis和Elasticache的ClusterAllFailedError: Failed to refresh slots cache.问题。. 这是我的集群配置const clusterOptions = { enableReadyCheck: true, retryDelayOnClusterDown: 300, retryDelayOnFailover:

charpy impact tests toughness|charpy impact test formula